BlackBuck launched its fuel sensor in 2024 - a key step toward transforming how trucking businesses monitor, manage, and optimize fuel usage. As the product completes one year on the road, it has grown from a simple concept into a fully integrated telematics solution powering fleets across Bharat.

In this behind-the-scenes blog, we walk through the journey of launching this new category - from early whiteboard sketches to real-world deployment. We dive into the product and engineering decisions, hardware challenges, firmware architecture, data modeling, field testing, and continuous improvements that helped shape the solution into the best Fuel Telematics Product for Bharat’s Fleet Operators.

From Blind Spots to Insights: Why Fuel Telematics Matters

Fuel accounts for nearly 40–50% of a trucker’s operating cost in Bharat, yet most fleets still rely on manual logs and assumptions to track consumption. At BlackBuck, we saw this as a critical gap - one that affects cost efficiency, trust, and operational control. Fuel management isn’t just about tracking how much goes into the tank; it’s about knowing where, when, and how it’s being used. Fuel telematics bridges this gap by converting raw fuel data into real-time, actionable insights - helping fleet operators cut costs, optimize refueling, and plan better routes.

One of the biggest challenges in this space is fuel theft. Despite existing checks, 4 out of 10 truck owners on the BlackBuck platform reported fuel pilferage at least once a year. This issue can’t be solved without deep visibility into fuel behavior - both at the vehicle and driver level. With our fuel sensor, operators can detect unusual drops, validate refueling events, and tie fuel usage back to driving patterns and route conditions. Combined with GPS and trip data, it unlocks powerful use cases: identifying inefficient driving behavior, reducing idling, improving route planning, and ultimately, building accountability across the fleet.

This is also part of our larger vision at BlackBuck - to build the operating system for Bharat’s Fleet Operators, where every moving part is tracked, optimized and made more efficient.

Choosing the Sensor

At BlackBuck, we chose capacitive sensors for our fuel telematics solution because they offer a reliable, low-maintenance method for measuring fuel levels. These sensors have no moving parts, making them less prone to mechanical failure and ideal for long-term use in harsh conditions. They work by detecting changes in capacitance between two electrodes placed vertically inside the tank. As fuel levels change, so does the capacitance - which is then converted into a digital signal that accurately reflects the fuel level.

Compared to float-based or ultrasonic sensors, capacitive sensors are better suited for commercial vehicle conditions. Float-based sensors are mechanical and can degrade over time due to vibration, wear, or fuel contamination. Ultrasonic sensors, while contactless, are sensitive to tank shape, foam, and installation height, often resulting in inconsistent readings. Capacitive sensors, on the other hand, offer a good balance of accuracy, stability, and durability - with simpler calibration and better performance across different tank shapes and fuel types.

The capacitive fuel sensor connects to the truck’s GPS device using either a wired interface or Bluetooth Low Energy (BLE). The GPS device acts as the communication gateway, transmitting fuel level data along with location, ignition status, timestamp and other attributes to BlackBuck servers via cellular network (2G/4G). This tight integration eliminates the need for a separate data module and ensures that every fuel reading is contextualised within the trip - enabling accurate detection of refuelling events, pilferage, and inefficiencies in real time.

Operational Challenges: BBPro-Assisted Calibration and Installation

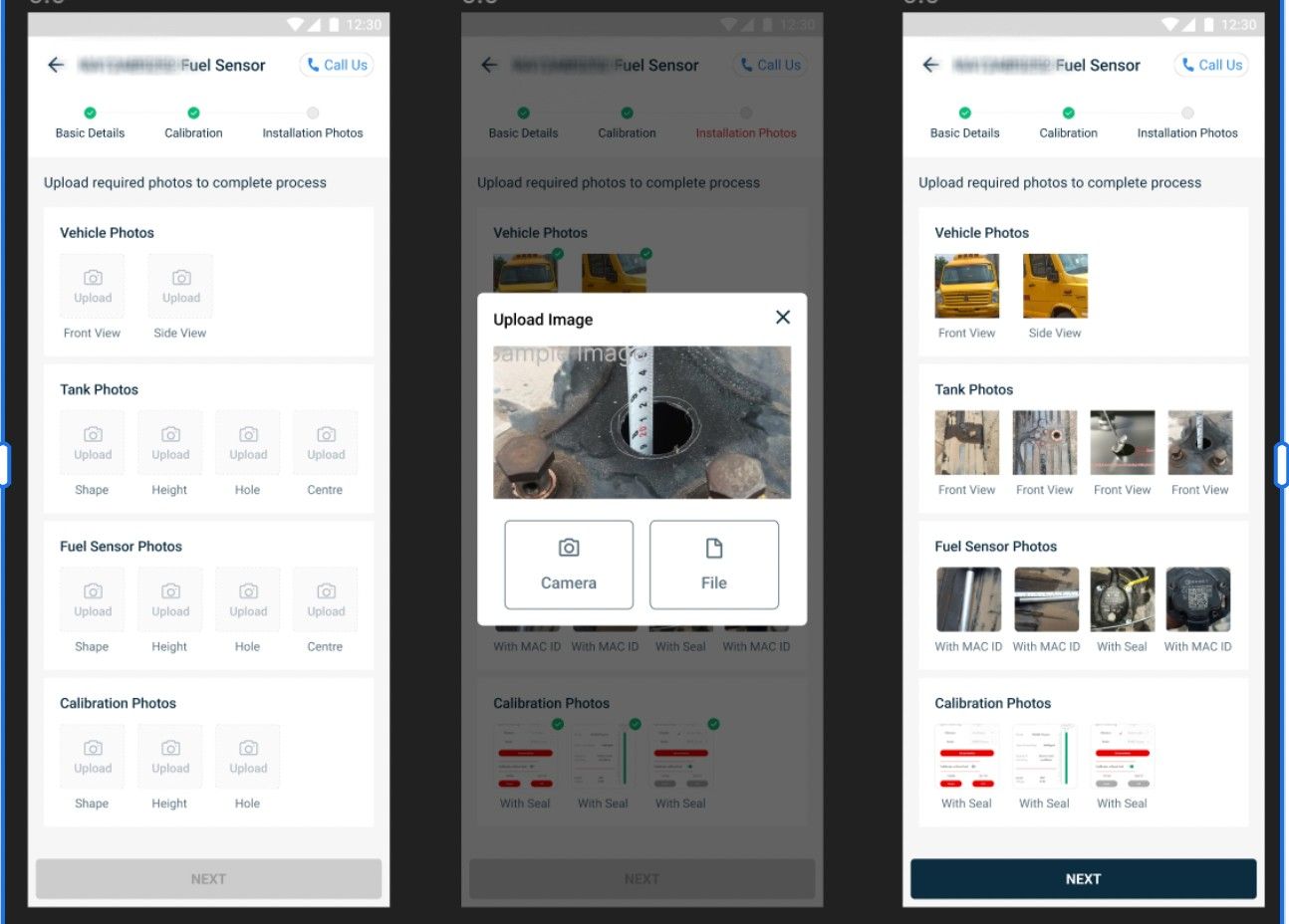

Deploying a fuel sensor across Bharat’s diverse trucking fleet isn't just about hardware - it's about enabling a consistent and reliable field experience, even in non-standard environments. To solve this, we developed BBPro, an internal technician-facing mobile app designed to assist with installation, calibration, validation, and quality control of the fuel sensor in real time.

In most cases, the sensor must be installed precisely at the vertical center of the tank, which requires technicians to drill a clean, accurately placed hole - often in dusty, oily, or poorly lit locations. The BBPro app guides technicians through each step of this process with checklist-based instructions, visual references, and automated validations. This reduces variability in install quality and minimizes the chance of errors.

Once installed, the sensor needs to be calibrated based on the truck’s actual tank profile. Since there’s no one-size-fits-all tank in Bharat, BBPro enables on-ground calibration by capturing readings at known fuel levels and generating a calibration curve automatically.

We also built in a maker-checker flow - where one technician performs the installation and calibration, and another remotely validates the signal strength, reading consistency, and mapping accuracy before the vehicle goes live. This double-layered approach ensures data integrity from day one, and gives confidence to both our internal ops teams and customers.

With BBPro, we were able to take what could’ve been a high-variability, error-prone field process - and turn it into a controlled, data-driven operation. It’s not just a support tool; it’s a critical part of making sure every sensor delivers value from the moment it’s deployed.

Engineering Challenges

Creating a reliable fuel telematics system for Bharat’s commercial fleet wasn’t just about engineering a sensor—it was about building a system that could survive noise, harsh conditions, and unpredictable driving behaviour, while delivering precise, contextual insights at scale. Here’s a deep dive into how BlackBuck approached the core engineering challenges across every layer of this journey.

Establishing Signal Fundamentals: From Lab to First Readings

We began in a controlled lab environment using clean diesel simulants and standard test tanks. The focus was validating whether capacitive sensors could reliably detect fuel level changes in a static setup.

- Signal Modelling: Fuel level changes altered capacitance between the probe’s electrodes. We converted these changes into a digital signal, mapping raw capacitance to measurable fuel levels.

- Resolution & Accuracy: Sensor resolution was tested across micro-level capacitance shifts. We validated up to 1 mm changes in fuel height, achieving ±1% accuracy under ideal conditions.

- Signal Delay: The delay between a physical change in level and its digital representation was benchmarked under various sampling rates, allowing us to optimise firmware for faster real-time updates.

Simulating Real-World Complexity in a Controlled Lab

While static testing gave us confidence in signal purity, real-world behavior was far more chaotic. We recreated field-like scenarios in our lab to simulate what the sensor would face in actual trucks:

- Slosh Simulation: We mounted tanks on a gimbal platform to mimic vehicle acceleration, braking, and cornering. This allowed us to model sloshing-induced spikes and refine our filtering logic.

- Vibration Emulation: High-frequency vibration plates were used to simulate engine idle and road-induced jitter, helping us profile mechanical noise.

- Thermal Variation: We ran tests under day/night thermal gradients and near-engine heat exposure to understand temperature-linked drift.

This phase allowed us to build a baseline noise profile library—mapping the shape, frequency, and amplitude of different noise types.

Noise Handling & Signal Smoothing

One of the biggest engineering hurdles was differentiating signal from noise. The fuel tank is a dynamic environment, and every movement or temperature change can introduce noise in the data. We broke this problem into several components:

Types of Noise Identified

- Mechanical Noise: Vibrations from engine idling or poor roads caused high-frequency jitter in readings.

- Sloshing Noise: Fluid inertia during sharp turns or braking created wave-like distortions, especially in half-filled tanks.

- Thermal Noise: Heat from the engine or external weather conditions affected fuel density, leading to gradual drift.

- Electrical Noise: Power supply fluctuations from alternators or GPS device voltage drops impacted ADC readings.

Our Approach to Smoothing

We evaluated, tuned and adopted multiple real-rime and state aware filters and build our own noise classification and noise smoothening engine. By continuously classifying and handling noise on the edge and in the cloud, we ensured fuel readings remained stable, actionable, and trustworthy—even in Bharat's toughest road and weather conditions.

From Hypothesis to Field: Iterative Learning with Actual Tanks

After simulating edge cases in the lab, we moved to on-vehicle trials. This is where hypotheses were validated or broken by real-world data.

- Tank Diversity: From cylindrical to rectangular, from flat to inclined mounts—each tank produced its own signature behaviour. We collected raw readings from hundreds of tank types to build data-backed calibration curves.

- Real Fuel Behaviour: Factors like return flow turbulence, vapor bubbles, and compartmentalised chambers created deviations we had not seen in test tanks.

With each deployment, we:

- Formed hypotheses on abnormal signals or event misclassification

- Correlated fuel readings with GPS, ignition, and trip context

- Refined detection logic and improved our filtering algorithms

Event Detection & Lag: From Raw Data to Real Incidents

Detecting real-world events like fuel theft and refuelling from noisy sensor signals required a system that could contextualise fuel data with trip telemetry. Refuelling and Theft detection typically involves a sudden upward spike or dip in fuel level respectively. But not every spike is a refuel event and not every dip is a theft. We built a system that correlated this with ignition OFF to ON pattern, location context, speed and time window. To improve precision , we combined raw signal with filtered and smoothed signal to improve classification.

Product Challenges

Before there was the fuel sensor, there was the fuel tracker. It worked by simply calculating a truck’s fuel consumption against its known mileage. From generic tracking to granular monitoring, BlackBuck’s fleet owners now check fuel levels, get refuelling alerts and know their consumption patterns in real-time. Integration has allowed users to view fuel data alongside other operational metrics, such as toll payments and load management. This holistic approach has simplified fleet management and helped operators use better routes, make fewer stops, and build a steady defence against discrepancies & deviants—all through a single digital dashboard.

Market Impact and User Adoption

BlackBuck’s fuel sensor, now a full-fledged electrochemical and GPS-integrated device, has seen widespread adoption across India’s trucking sector. As of June 2025, BlackBuck has over 400,000 active telematics devices in the field, with the fuel sensor playing a significant role in driving this growth. The device’s success is grounded in BlackBuck’s on-ground technician network, which drives the wheel of execution through installation, maintenance, and support activities across the country.

The Next Milestone

BlackBuck’s fuel sensor marks its first full year on the road—but this is just the beginning. Our goal remains clear: to build focused, reliable solutions tailored for the unique needs of Indian truckers. As we enter the next phase, we're evolving from simple real-time fuel monitoring to delivering deeper insights—combining fuel data with critical engine parameters, vehicle health metrics, and driver behavior patterns.

Leveraging AI and machine learning, we're working towards predictive fuel analytics - anticipating when and where your truck might run low based on driving habits, vehicle load, and terrain. This helps fleet operators plan smarter, more efficient routes.

And we're not stopping at trucks. Our vision is to extend this innovation to other commercial vehicles, including construction equipment like earthmovers, JCBs, and generator sets.

Title image by Photo by USGS on Unsplash